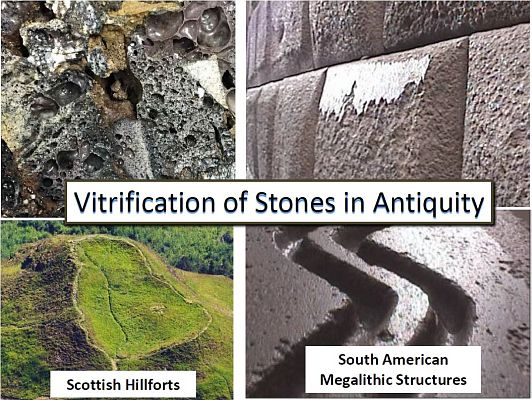

Examination of the chemistry of vitrification to determine if there is a link between the vitrified stones that are found in Iron Age Scottish hillforts and in the ancient megalithic stone work of South America

Transcript:

Vitrification of stones in antiquity. This video examines the chemistry of vitrification to determine if there is a link between the vitrified stones that are found in Iron Age Scottish hillforts and in the ancient megalithic stone work of South America.

The vitrified stones in the walls of the hillforts in Scotland appear haphazard and look like they were the result of accidental or intentional fires rather than the deliberate application of heat technology. The stones are fused with evidence that gas bubbles formed within the melted rock, and the vitrified walls have a coarse appearance that is not aesthetically pleasing.

By contrast, the vitrification of the megaliths in South America seem to have been made using well-established technology. Weathering has crumbled away parts of the vitrified crust in some stones, revealing a rougher surface underneath. Many stones have retained their sheen for hundreds or perhaps thousands of years.

A high temperature is required to melt stone. Lava from volcanoes is produced at temperatures of about 1200 degrees Celsius. After cooling, lava can vitrify to form glasslike substances, such as black obsidian. Ordinary wood fires usually are not hot enough to melt stones.

A study of the Dun Deardail hillfort in Scotland found that the tops of the stone walls were the most heavily vitrified. This can be explained if ashes of a burning superstructure on top of the wall fell on the rocks during a fire. This will become clear when we take a look at Iron Age fort construction and vitrification with wood ashes.

The Iron Age fort of Biskupin in Poland was occupied from about 800 to 475 BC. Its reconstruction helps to visualize the typical features of Iron Age forts. The ramparts or defensive walls of Iron Age forts were thick to be able to hold wooden watch towers with thatched roofs to protect the guards from the rain and cold. The thick walls allowed defenders to climb on top and fight the enemy with slings, arrows and other projectiles. The Scottish forts were constructed with wooden beams and drystone instead of the packed dirt of the Polish forts. For defense, the forts were surrounded by moats and fortified with stockade fences. When the wooden structures and thatched roofs on top of the ramparts caught fire, the hot ashes dropped on the stones of the wall and acted as a flux that lowered the melting point of the rock wall to cause vitrification. Ash glazes are ceramic glazes made of the ash of wood or straw. A wood fire can provide the chemical components for vitrification, particularly when burning timbers and a thatch roof fall on top of the stone ramparts. Wood ash contains 25 to 45 percent of calcium carbonate, about 10 percent of potash, and less than one percent phosphate and other trace elements. Potash is mainly potassium carbonate. Ash glazing began initially by accident around 1500 BC in China during the Shang Dynasty as ash from the burnt wood in the kiln landed on pots. Around 1000 BC, the Chinese started adding the ash before the pot went into the kiln.

Ash glaze was the first glaze used in East Asia, and contained only ash, clay, and water. In Korea, a traditional ash glaze is still used today for Onggi pots used for cooking and for fermenting foods such as kimchi. The glaze consists of finely ground wood ash and leaf mold made into a thin slurry that is applied to the pots by dipping. After the pots are fired in a kiln they come out with a lustrous vitrified sheen from the wood ash glaze. This traditional glazing technology provides the basis for the hypothesis that the vitrification of the Scottish forthills was caused by accumulation of wood ashes on top of the stone walls when the fort was on fire.

We now take a look at the vitrified megaliths of South America. Graham Hancock's web site has an article by Jan Peter de Jong and Christopher Jordan that describes the vitrified stonework in the Inca vestiges of Peru. The article mentions that a small stone sample from the Peruvian site called Tetecaca was tested and that the main body of the stone shows the spectral composition of limestone with high levels of calcium, carbon, oxygen and minor trace elements. This is expected since the Sacsayahuaman archaeological park is on a karst landscape of limestone bedrock.

The vitrified surface of the stone shows a very different spectrum of elements compared to the limestone body. The main difference is that silicon is the predominant component and oxygen, aluminum and magnesium are also significantly higher than the body of the stone. Calcium and carbon are much lower than the body sample. The silicon, aluminum and magnesium seem to indicate that a material was added to the surface of the stone. We should keep in mind that oxygen, silicon and aluminum are the three most common elements of the Earth's crust and that they are the constituents of clay minerals which are hydrous aluminum phyllosilicates with molecular formulas containing 3 atoms of silicon or aluminum for every 4 atoms of oxygen.

The chemical decomposition of limestone with heat and the reaction of the resultant compounds with water and carbon dioxide in the air can shed some light on the process of vitrification. Limestone is basically calcium carbonate, which decomposes at a temperature of 825 degrees Celsius into calcium oxide and carbon dioxide. Calcium oxide is commonly called quicklime, and it reacts with water to form calcium hydroxide and heat. Calcium hydroxide, also called slaked lime, is a component of bricklayer's mortar and it turns back into limestone by reacting with carbon dioxide in the air. From these reactions, it is clear that a cycle of heating and cooling limestone can change the characteristics of the surface.

Let us say that a slab of limestone is heated so that quicklime forms on its surface. After the slab cools down, the surface may be covered with a layer of moist clay that will integrate the aluminosilicates of the clay with the quicklime in a thin layer that hardens into a type of Portland cement, which is basically a mixture of quicklime, silica and alumina. Variations of this procedure may have been used for vitrification of some South American limestone surfaces. I wanted to explore these ideas, so I designed an experiment to see if wood ashes could have contributed to the Scottish hillfort vitrification.

I spooned ashes on top of some feldspar stones that I had collected from a local creek. Right away, it was evident that the ashes on the stones become incandescent within a few seconds, which is not the case when the propane torch is applied directly to the stones. It is amazing that the ashes seem to intensify the heat of the fire even though they do not contribute energy to the burning process. After the stones cooled down, I brushed off the ashes and found evidence of vitrification along some of the edges. The amount of vitrification is not large enough to be totally convincing, but it seems that the ashes did play a role in helping to melt the rock. More experiments are needed. My megalithic vitrification experiment tried to test some ideas regarding the use of clay and ashes.

First, I created a slurry of clay, ash and water. For this experiment only the clay with its aluminosilicates might have been sufficient since the experiment involved only limestone and, thus, the fluxing action of the ashes on silicate stones was not needed.

My limestone sample was a piece of marble left over from kitchen remodeling. I painted one side of the piece of marble with the ash-clay mixture. The mixture was lumpy because the ashes were not processed by grinding. Just like in the previous experiment, the ashes in the clay seemed to intensify the heat of the torch. The large pieces of ash started to glow immediately and the surface became incandescent. The heat was focused in one area, rather than being distributed on the whole surface.

In retrospect, this experiment was poorly designed, but this is what experiments are for. You find out what doesn't work and you try something different the next time. The heat was so intense that the piece of limestone cracked. Also, the section that was overheated developed too much calcium oxide, which expanded when it was washed with water creating a hole in the limestone block.

But there is something positive. This image shows a section of the marble that was heated to a lower temperature. Notice that the right part has a smoother texture where the saw lines on the marble are less prominent. Experimentation with clay slurries of different compositions, various temperatures, times of heating and exposure to water could eventually produce results equal those of the megalithic cultures, but we are very far from that. Right now, we are just trying to learn how to cook without recipes or training.

Many people want to find out how the megalithic glazing was accomplished. This is your opportunity to contribute to science. Start a megalithic glazing club where each member of the club tries a different technique. Figure out what works best and try to improve it. This is not high tech. Anybody who has an outside grill or who can make a campfire can participate. It only requires ashes, clay, water, fire, imagination and persistence. Wear safety goggles, don't touch the hot stones, and don't set your house on fire.